A symbolic drink of Japan, sake is an alcoholic beverage made by fermenting a specially selected rice variety, using a mold (kōji) and yeast.

Its complexity lies in a simultaneous double transformation: the starch in the rice is gradually converted into sugar by the kōji, while these fermentable sugars are in turn transformed into alcohol by the yeast as they are produced. This unique process requires precision, strict hygiene, and careful control of temperature and fermentation time.

From rice polishing to bottling, every stage plays a crucial role in shaping the final aromatic profile of the sake.

This article takes you through each step of the sake-making process, following the traditional Japanese methods.

Step 1 - Polishing the rice

The production of sake begins with rice polishing (seimai), a process that removes more or less of the outer layers of the grain. These layers, rich in proteins and fats, are responsible for rich and intense aromas, and their presence has a significant impact on the final style of the sake.

At the center of the rice grain lies the starch, the key element for alcoholic fermentation. This core also releases the most delicate aromas, often described as soft and fruity.

The polishing ratio (seimaibuai) is a fundamental criterion in sake production. A 70% polishing ratio means that 30% of the grain has been removed—this is referred to as the residual ratio.

Several classifications are defined by this polishing ratio:

- Junmai: residual ratio above 60%

- Ginjō: residual ratio below 60%

- Daiginjō: residual ratio below 50%

Some extremely rare and valuable cuvées reach polishing ratios under 10%, meaning that over 90% of the original rice grain is removed.

This polishing process is carried out slowly, sometimes over 40 to 50 hours, to avoid damaging the grain. For premium sake, producers typically use sake-specific rice (shuzō kōtekimai), cultivated for its high starch content, concentrated in the core of the grain, to optimize the polishing process.

Step 2 - Washing, soaking and cooking the rice

Once polished, the rice is washed to remove the residual polishing powder, known as nuka. This step plays a key role in enhancing the aromatic clarity of the future sake.

Next, the rice is soaked in pure water to reach the optimal moisture level at its core, ensuring even and effective steaming. The higher the polishing ratio, the shorter and more precise this soaking phase must be.

Once polished, the rice is washed to remove the residual polishing powder, known as nuka. This step plays a key role in enhancing the aromatic clarity of the future sake.

Next, the rice is soaked in pure water to reach the optimal moisture level at its core, ensuring even and effective steaming. The higher the polishing ratio, the shorter and more precise this soaking phase must be.

Step 3 - Making the kōji

Kōji is one of the key elements in the sake-making process. It consists of steamed rice inoculated with the mold Aspergillus oryzae. This microorganism releases enzymes, primarily amylase, which convert the rice starch into fermentable sugars.

Kōji is cultivated in a warm, humid room called the kōji muro for about 48 hours. During this time, brewers:

- aerate the rice to prevent excessive temperature rise,

- manually monitor the development of the mycelium,

- stir the rice regularly to ensure even growth.

The mold forms a distinctive fluffy texture on the surface, accompanied by a characteristic sweet aroma. Kōji typically makes up 20 to 25% of the total rice mass used in the brewing process.

Step 4 - Preparing the tank foot (shubo or moto)

Before starting the main fermentation, a small fermentation starter is prepared: the shubo, also known as moto. It’s a mixture of steamed rice, kōji, water, and yeast.

This starter serves two main purposes:

- to cultivate a strong population of yeast,

- to create an acidic environment that suppresses the growth of unwanted bacteria.

Fermentation of the shubo lasts 10 to 15 days when lactic acid is directly added (known as the sokujo method), but can extend to up to a month when using traditional techniques like kimoto or yamahai, which rely on naturally occurring lactic acid bacteria to develop acidity.

Step 5 - Main fermentation (moromi)

The moromi is the main mash. It consists of the shubo, to which the remaining steamed rice, kōji, and water are gradually added. This fermentation takes place in three successive stages, a process known as sandan shikomi.

Fermentation continues for 18 to 32 days at controlled temperatures (generally between 8°C and 15°C). This process is known as multiple parallel fermentation, as saccharification and alcoholic fermentation take place simultaneously. This unique method enables sake to reach high alcohol levels—up to 20%—without distillation.

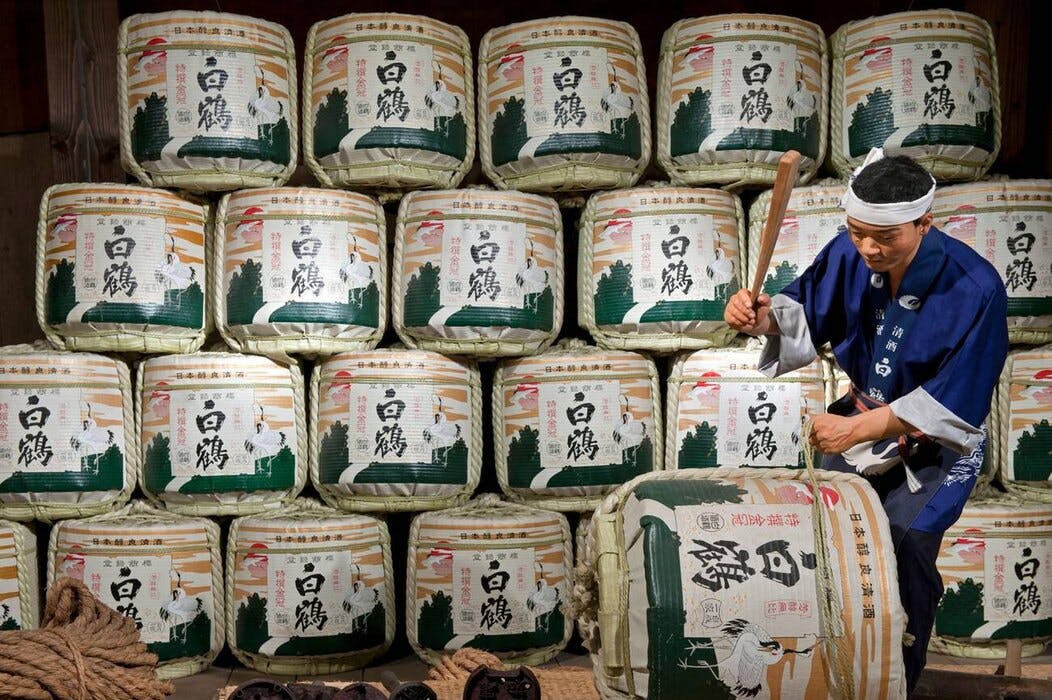

Stage 6 - Pressing

When the moromi is deemed ready, it is pressed to separate the liquid (sake) from the solid residues (sake kasu).

There are three main pressing methods:

- Mechanical press (yabuta): the most common industrial method.

- Traditional box press (fune): the mash is poured into cloth bags stacked in a large wooden box. Pressure is applied gradually from above, allowing a gentle extraction. This slower, artisanal method is often preferred for high-end sakes.

- Drip pressing with hanging bags (fukuro-tsuri): the liquid drips naturally without mechanical pressure. Reserved for craft cuvées, sometimes referred to as shizuku-zake (“drip sake”).

The solid lees, rich in proteins, can be reused in cooking, agriculture, or for making shochu, a traditional distilled Japanese spirit.

Step 7 - Clarification, pasteurization and dilution

The raw sake (genshu) is then clarified and stabilized. Depending on the desired style, it may undergo several treatments:

- filtered with activated charcoal to achieve a perfectly clear appearance,

- pasteurized once or twice to prevent any renewed fermentation (non-pasteurized sakes are known as namazake),

- diluted with pure water to reach a final alcohol content between 12% and 18% ABV.

Some producers opt for unfiltered (muroka) or undiluted (genshu) expressions, resulting in bolder and more intense profiles.

Step 8 - Maturation and bottling

Finally, the sake is stored at low temperature for several weeks to several months. This maturation phase helps to stabilize the aromas, soften the perception of alcohol, and smooth out the mouthfeel.

The sake is then bottled and can be kept for several months to several years, depending on its style. Non-pasteurized sakes must always be stored under refrigeration.

TO DISCOVER SAKE FURTHER

La Maison du Whisky has three boutiques in Paris :

In each of these boutiques, you'll find a wide selection of whiskies, rums, sakes, and other fine spirits.

Follow our tasting calendar for upcoming events, or visit the Golden Promise Whisky Bar, which offers an extensive selection of whiskies and other spirits by the glass.

You can also discover other articles about calvados.